KEY TAKEAWAYS:

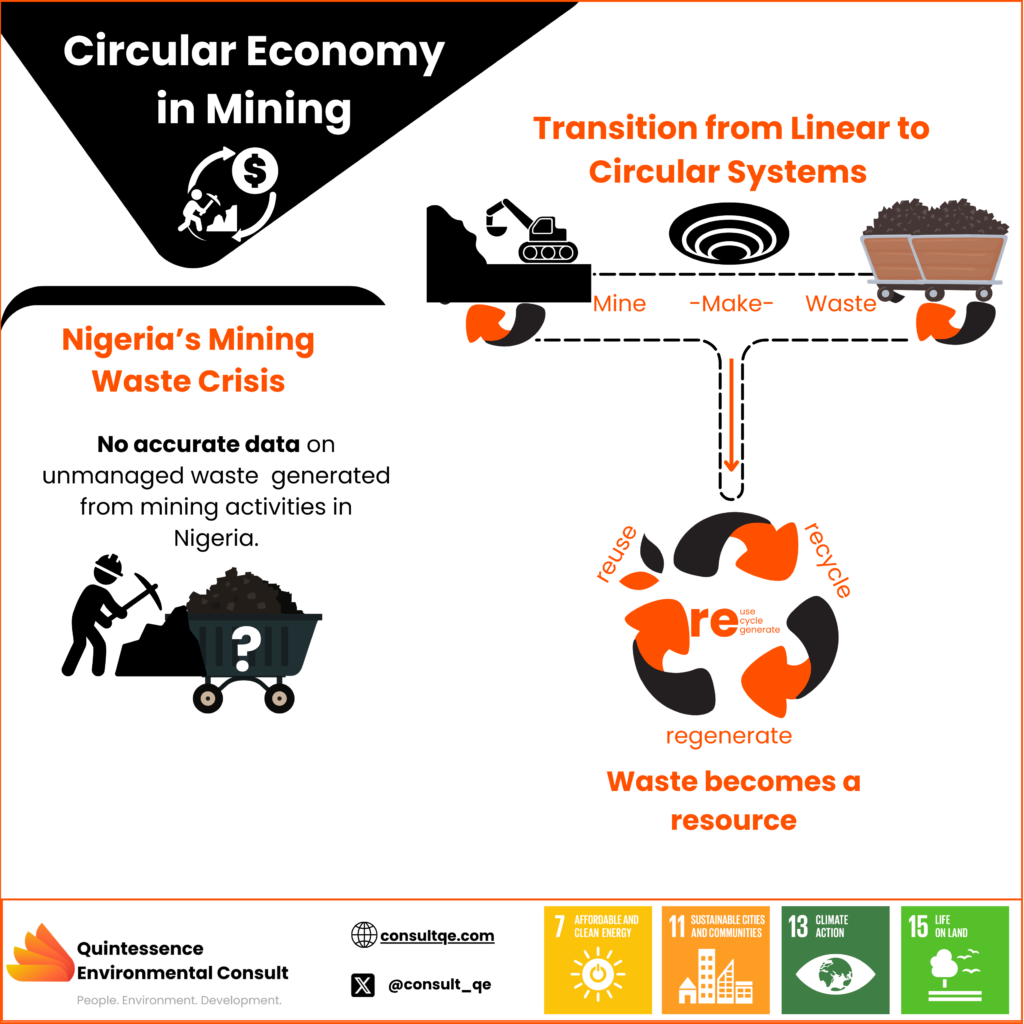

- Circular Economy Concept in Mining: The article highlights the shift from the traditional ‘take-make-waste’ model to a circular economy in mining, where waste is reused, recycled, and regenerated.

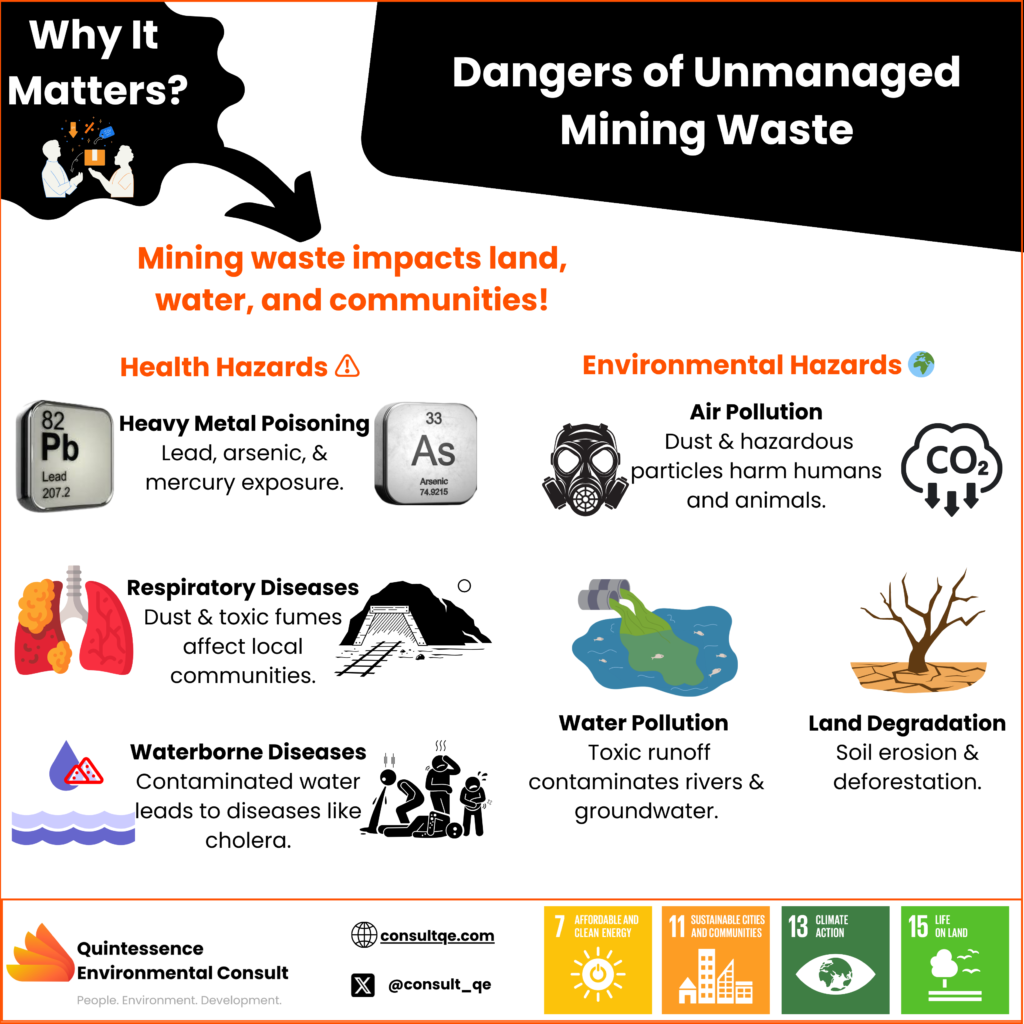

- Nigeria’s Mining Waste Challenge: Mining activities in Nigeria, particularly artisanal operations, generate significant waste that exacerbates environmental issues such as land degradation, water pollution, and health risks.

- Economic Opportunities in Recycling Mining Waste: Repurposing mining waste offers various benefits, such as using tailings in construction, recovering valuable minerals like rare earth elements and lithium, and treating mine water for agricultural use.

- Global Inspiration for Nigeria: Examples from countries like Australia and Canada illustrate how mining waste recycling can contribute to sustainable practices. Australia converts tailings into industrial bricks, while Canada focuses on extracting critical minerals from waste to support clean energy transitions.

- Call for Policy and Innovation: The article advocates for stringent regulations, investment in advanced technologies like bioleaching, public-private partnerships, and educational initiatives.

INTRODUCTION

Our nation Nigeria, although partially dependent on mining explorations for its economic growth has a pressing challenge that remains largely overlooked. Mining Waste is a hidden untapped treasure that could revolutionize our economy whilst protecting the environment. Hence, the concept of a circular economy in mining, whereby waste transformed into wealth, reduces environmental hazards, and fosters sustainability.

WHAT EXACTLY IS A CIRCULAR ECONOMY IN MINING?

A circular economy moves away from the traditional ‘take-make-waste’ model. Instead of discarding resources after use, materials are reused, recycled, and regenerated (Yiqing Zhao et al., 2011). In mining, this means utilizing waste products as valuable resources.

Mining waste typically includes rocks, tailings, slags, and water contaminated during mineral extraction. While these materials have historically been abandoned or disregarded, advancements in technology and sustainable practices now allow them to be repurposed for economic and environmental gain. Imagine a Nigeria where the mountains of tailings from artisanal mining sites become raw materials for construction such as Bricks, Concrete, Foam ceramic and so on.

NIGERIA’S MINING WASTE PROBLEM: A GROWING CONCERN

Nigeria’s mining sector is expanding, particularly with activities in gold, lead, zinc, lithium, and other minerals. However, unregulated mining, especially artisanal mining generates an immense amount of waste and improper disposal exacerbates land degradation, water pollution, and health risks. In states like Zamfara, Niger, and Plateau, massive dumps of mining tailings dot the landscape, posing serious health risks due to heavy metals like lead, cadmium, and arsenic causing the death of Over 400 children due to exposure to lead-contaminated dust from artisanal gold mining waste (BBC News, 2010). Similarly, in Plateau State, abandoned tin mines have left behind pits that accumulate contaminated water, posing long-term environmental and public health risks (Ogundiran & Osibanjo, 2009).

Take a look at the numerous granite quarries spread throughout the country, their inert waste has been classified on the European List of Waste under code 01 04 13, “wastes from stone cutting and sawing other than those mentioned in 01 04 07” (European Comission, 2000). It has a heavy environmental impact due to its adverse effect on soil permeability, for it hinders water seepage to the lower layers, which in turn affects aquifer recovery and plant life. It also constitutes a risk to human health due to the small percentage of crystalline silica in the fines which, if inhaled, may cause lung disease of varying severity (Singh et al., 2016).

TRANSFORMING MINING WASTE INTO ECONOMIC OPPORTUNITY

- Recycling Tailings for Construction and Infrastructure

The mining circular economy promotes sustainable practices by recycling and repurposing mining waste and byproducts. Materials like slag, fly ash, and calcium sulfate are utilized in construction and manufacturing industries, reducing waste and environmental impact. Residual heat is repurposed for heating and fermentation energy. Treated wastewater from mining operations serves as cooling water or process water, conserving resources and preventing pollution. This approach addresses resource scarcity, minimizes waste, mitigates environmental damage, and enhances resource efficiency, contributing to sustainable economic development.

Mining tailings, particularly from granite or limestone extraction, can be processed into aggregates for building roads, bridges, and housing. When managed appropriately, these materials reduce dependency on virgin resources like river sand, which are being overexploited. The abandoned tin mine tailings could be repurposed for road construction projects, particularly in rural areas where infrastructure remains underdeveloped. This approach creates jobs whilst addressing Nigeria’s critical infrastructure deficit.

Repurposing mining tailings for construction offers economic and environmental benefits, but it also raises health and safety concerns due to residual toxins like silica dust, heavy metals, and radioactive elements. Inhalation of crystalline silica can cause lung diseases such as silicosis, while exposure to heavy metals like lead and arsenic poses serious health risks. Therefore, rigorous safety standards must be enforced to ensure safety in repurposing the waste, including;

- Comprehensive Material Testing: Ensuring tailings are free from hazardous levels of toxins before use.

- Proper Processing Techniques: Using encapsulation, stabilization, and chemical treatment to neutralize harmful substances.

- Workplace Safety Measures: Implementing dust control systems, protective gear, and regular health monitoring for workers.

- Regulatory Compliance: Establishing strict national guidelines aligned with global best practices (e.g., WHO, EPA) for safe waste utilization

Other uses for tailings include;

- Shotcrete: Tailings can be used to make commercial shotcrete.

- Concrete: Tailings can be used to make concrete products for mine roads.

- Insulation: Tailings can be used to make insulation.

- Foamed products: Tailings can be used to make foamed products

- Recovering Valuable Minerals from Waste

What many fail to realize is that mining waste often contains residual amounts of valuable minerals. Advances in technology now make it economically viable to recover precious metals such as silver, and rare earth elements (REEs) from tailings. In China, rare earth elements are extracted from mine tailings and used in electronics, renewable energy technologies, and electric vehicle components.

Nigeria, with its untapped lithium and other critical minerals, could adopt similar practices to supply materials needed for the global energy transition.

- Reusing Mine Water for Agriculture

Mine water can come from two primary sources: groundwater seepage into mine excavations or wastewater generated from ore processing. Often, this water becomes contaminated with chemicals, making it hazardous for direct use. However, with proper treatment, both types of mine water can be purified and repurposed for irrigation in arid regions of Nigeria like the northern states.

Imagine using treated mine water to irrigate farmlands in Jos, Bauchi, Niger and other states. This would not only combat water scarcity but also promote food security which is a key challenge in many parts of the country.

ENVIRONMENTAL AND ECONOMIC BENEFITS

The benefits of recycling mining waste are twofold: environmental sustainability and economic growth. By implementing circular economy principles, Nigeria can:

- Reduce Pollution: Recycling mining waste limits environmental contamination, protecting water bodies, soil, and ecosystems.

- Create Jobs: From processing facilities to research and development, the circular economy stimulates job creation in both urban and rural areas.

- Boost Revenue: Recovered minerals and repurposed waste generate revenue streams for the government and private investors.

- Promote Energy Transition: Nigeria’s role in the global clean energy market could be strengthened by recycling lithium, rare earth elements, and other critical minerals from mining waste.

GLOBAL INNOVATIONS

Countries like Australia and Canada are already leading the way in adopting circular economy principles in mining. In Australia, mining companies recycle tailings into industrial bricks. This process is called geopolymerization and uses alkaline solutions to create eco-friendly bricks. In Canada, research is underway to extract cobalt and nickel from mining waste to support the electric vehicle industry. This research includes developing new technologies to process and refine minerals from waste and recycling used batteries. According to the IEA, recycling could reduce global primary supply requirements for copper, nickel, lithium and cobalt by 10 to 30% by 2040.

Nigeria can take inspiration from these global innovations. By investing in technology, infrastructure, and policies that support waste recycling, the country can position herself as a sustainable mining powerhouse in Africa.

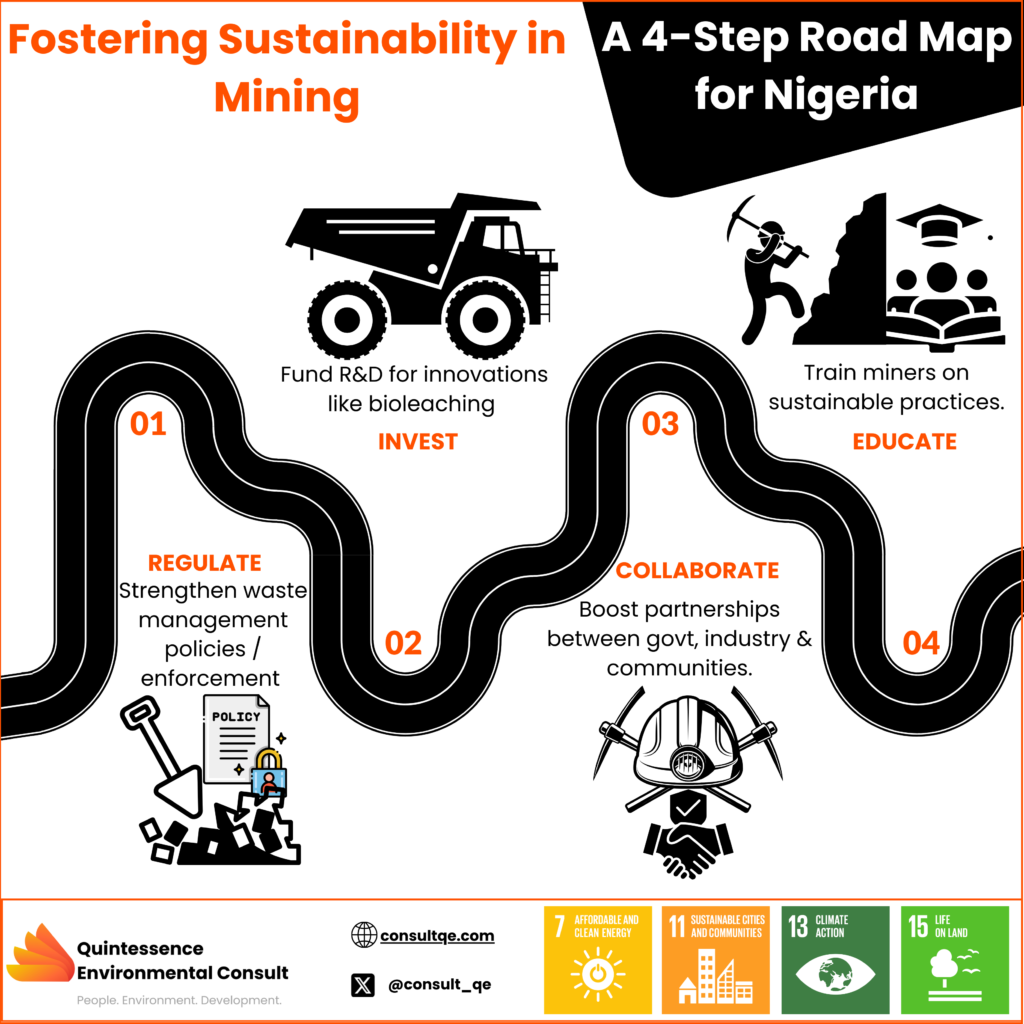

- Regulation and Monitoring: Nigeria needs stringent policies to ensure mining companies responsibly manage and recycle waste.

- Investment in Technology: Technologies like bioleaching, chemical extraction, and advanced water treatment systems must be adopted.

- Public-Private Partnerships: Collaboration between the government, private sector, and research institutions can drive innovation in mining waste recycling.

- Education and Awareness: Artisanal miners and communities must be educated on the economic potential of mining waste and the importance of safe handling practices.

- Stakeholder Engagement: Local communities, artisanal miners, and NGOs should be actively involved in co-designing solutions to ensure local buy-in and effective implementation. This includes training programs, participatory decision-making, and access to sustainable mining techniques.

CONCLUSION: NIGERIA’S HIDDEN TREASURES AWAITS The circular economy in mining offers an incredible opportunity to address the country’s economic, environmental, and social challenges. Mining waste, once seen as a liability, can become a goldmine for infrastructure development, mineral recovery, and job creation.By rethinking our approach to waste, Nigeria can unlock hidden value, reduce environmental degradation, and set the stage for a sustainable future. The question now is: are we ready to embrace this change and harness the power of circularity in mining?

REFERENCES

BBC News. (2010). Nigeria lead poisoning: Death toll rises in Zamfara.

European Comission, 2000. Comission Decision 2000/532/EC. European List of Waste. Brussels (Belgium), p.31

Ogundiran, M. B., & Osibanjo, O. (2009). Heavy metal concentrations in soils and accumulation in plants growing in a deserted tin mine in Nigeria.

Singh, S., Nagar, R., Agrawal, V., 2016. Performance of granite cutting waste concrete under adverse exposure conditions. J. Clean. Prod. 127, 172-182.

Yiqing Zhaoa, Li Zanga, Zhongxue Lia, Jiexuan Qina., 2011. Discussion on the Model of Mining Circular Economy. Energy Procedia 16 (2012) 438 – 443

External Links

https://internationalcopper.org/resource/the-role-of-mining-in-the-circular-economy/