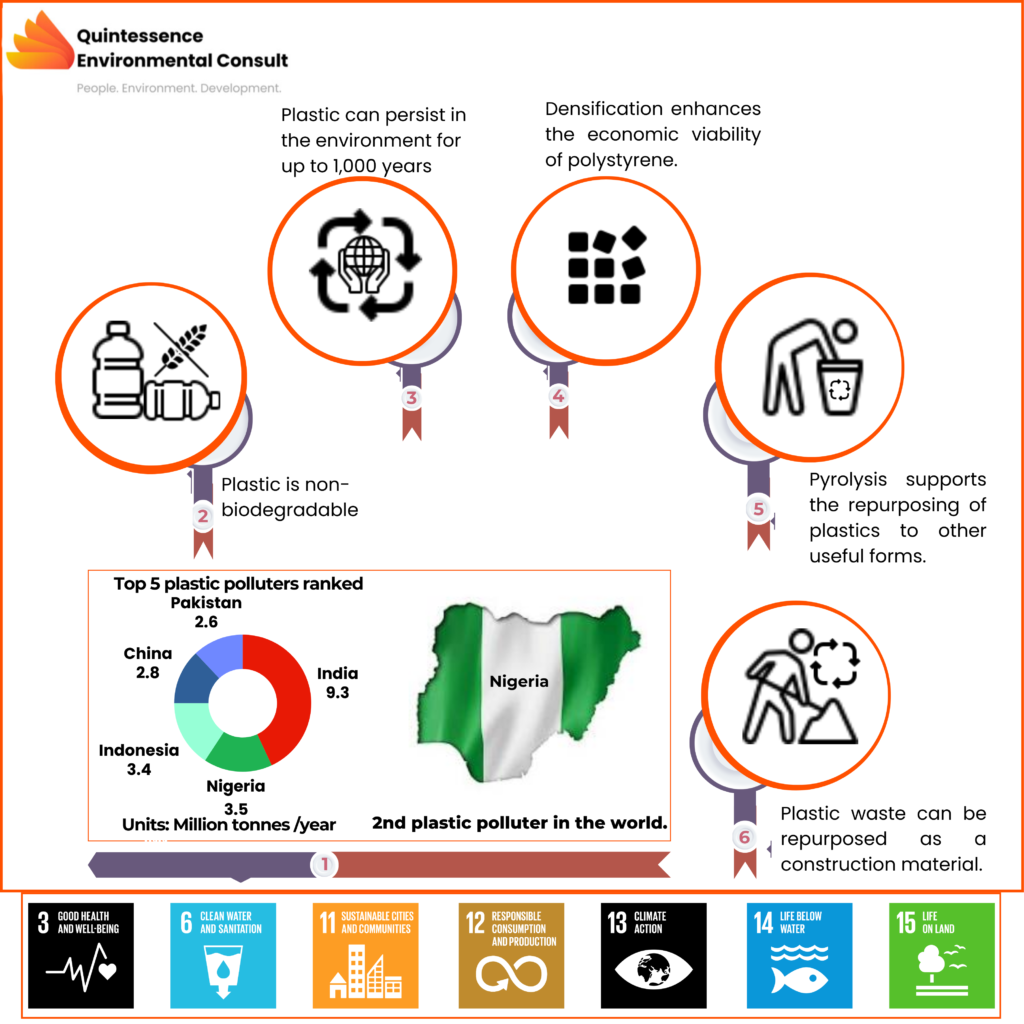

The Foundation for Investigative Journalism reports that Nigeria is now the second largest plastic polluter in the world only behind India.

TAKEAWAYS

Innovative Recycling Techniques:

- Densification: Enhancing the economic viability of polystyrene by compressing it into blocks, easing transportation costs and making recycling more profitable

- Plastic pellets and flakes: Polyethylene terephthalate (PET) bottles are collected, sorted, washed and processed into pellets and flakes and sold to advanced recycling companies

- Pyrolysis: A waste to chemical technology that converts plastics into pyrolysis oil which may be processed into new plastic or other chemical. A pilot pyrolysis unit by BASF Nigeria is being proposed for Lagos.

- Plastics in Construction: Innovative use of plastic waste as building materials is gaining traction. Examples include PET bottles filled with sand to construct buildings and plastic sand composites for bricks and tiles for pavements.

- A UNEP Intergovernmental Negotiating Committee (INC) on plastic pollution is developing a legally binding international instrument to advance the management of plastic pollution.

- For Nigeria to remain competitive in plastic management it must take advantage of available financial technological instruments.

- The UNEP Finance Leadership Group on Plastics, a core group of banks and insurers is charged with developing financing framework for plastic pollution.

BACKGROUND

Global plastic production is estimated at over 460 million tons annually, much of which are discarded as waste after use. Plastic is a non-biodegradable material and can persist in the environment for 100 to 1,000 years, constituting significant health and environmental challenges. It is estimated that Nigeria generates 3.5 tons of plastic waste annually making it 2nd globally after India.

The world is plagued with excessive plastic waste and Nigeria is no exception. As plastic waste clog water drainages, it has been identified as one of the factors contributing to the severity of flooding in Nigeria. In spite of the technological limitation of plastic waste management in Nigeria, there are interesting innovative and home-grown ideas that deserve acknowledgment, support and promotion in order to ameliorate the disastrous effect of plastic. Meanwhile, plastics come in different compositions and are not all equal. The most common plastics in use are: Polypropylene (PP), Polyethylene Terephthalate (PETE or PET), Polyvinyl Chloride (PVC) and Acrylonitrile-Butadiene-Styrene (ABS).

PROCESSING PLASTIC WASTE FOR EXPORT

PET bottles are the most sought-after type of plastic by recycling companies. The demand for recycled polyethylene terephthalate (rPET) is increasing due to regulations aimed at reducing virgin plastic production and encouraging Extended Producer Responsibility (EPR). The global market for recycled PET is estimated to exceed $5 billion, presenting investment opportunities for recycling companies in Nigeria. Local companies like Labacorp Energy, Alef Recycling, and others collect, sort, wash, and process PET bottles into flakes and pellets for export.

DENSIFICATION OF PLASTIC TO ENHANCE ECONOMIC VALUE

Although polystyrene can also be recycled, its high processing costs make it less appealing to local recyclers in Nigeria. However, densification can enhance its economic viability by making transportation cheaper and easier. Wecyclers Corporation is partnering with BASF Nigeria to densify polystyrene waste into compact blocks with a density of 950-1050 kg/m³, which will reduce shipping costs to larger recycling firms abroad.

PLASTIC AS A BUILDING AND FASHION MATERIAL

Plastics can be utilized in various construction applications. For example, PET (Polyethylene terephthalate) bottles filled with dry sand, wet sand, or air and reinforced with cement can act as building blocks. In 2011, the Development Association for Renewable Energies built Africa’s first prototype house using sand-filled PET bottles in Yelwa, Kaduna State, Nigeria. This structure is about 18 times stronger and twice as cost-effective as conventional blocks, providing excellent insulation with a consistent temperature of 18°C.

Figure 1. Social Innovation Academy (SINA) Project (Source: https://www.greiner.com/en/blog/detail/houses-made-from-plastic-bottles-yes-that-exists/)

Another innovative material is plastic sand composite, created by heating a mixture of plastic and sand, where the plastic serves as a binder. This composite can be used to produce bricks, manhole covers, and more. In Kenya, Gjenge Makers LTD and in Ghana, Nelplast Eco Ghana LTD are successful startups using extrusion machines to manufacture plastic sand composites for building materials and paving tiles.

While it’s uncertain if similar machines exist in Nigeria, some startups are reportedly using basic methods to heat mixtures of plastic and sand to make bricks and tiles. A notable example is Ifrique Eco Solutions, founded by Instissar Bashir Kurfi, which produces composites from nylon plastic using open-air heating. Additionally, nylon can be repurposed for fashion items. Planet 3R, founded by Adegoke Lasisi, creates beautiful products like bags, shoes, and purses from water sachets and other nylon and textile waste.

Figure 2. Eco-Tiles for Pavements (Source: ifrique.com)

Figure 3. Laptop Bag (Source: https://www.planet3r.com/project/laptop-bag/)

PLASTIC WASTE-2-CHEMICAL USING PYROLYSIS

Pyrolysis is a thermochemical recycling technology that breaks down plastic into its monomeric units. The product of this process is known as pyrolysis oil. The oil may serve as fuel or secondary raw material for the production of other plastic products. Unlike other recycling processes, pyrolysis does not require sorting and plastic produced from pyrolysis oil is of higher quality compared to products from tradition recycling technology. However, this technology is beyond the reach of local plastic recycling companies in Nigeria. In 2023, BASF Nigeria proposed establishing the country’s first pyrolysis unit in Lagos. If successful, this pilot project could be expanded nationwide. The oil produced from this process could generate enough energy to operate the unit, with excess oil collected and shipped to centralized locations for export as secondary raw materials for various products.

OTHER OPPORTUNITIES AND THE FUTURE OF PLASTIC WASTE MANAGEMENT

Virgin plastic is less expensive than recycled plastic, making it crucial for policies to encourage plastic recycling while discouraging the use of virgin plastic. This goal aligns with the core mission of the UNEP Intergovernmental Negotiating Committee (INC) on plastic waste, which is developing a legally binding international framework for managing plastic waste. The ability of governments worldwide to implement this framework after ratification will largely depend on the technological advancements of each member state. Thus, it is vital to understand Nigeria’s current position in the waste management value chain. Nigeria must ensure it does not hinder the regional progress toward a fully circular economy in the plastic sector. To achieve this, Nigeria needs to leverage all available financial resources and technologies to keep pace with global developments. Financial instruments are being developed by the ‘Finance Leadership Group on Plastics’, a core group of banks and insurers with total assets of USD 9.8 trillion.

CONCLUSION

Plastic is one of the raging environmental challenges facing the globe today. In order to tackle the menace of plastic waste, recycling is a highly valued option in the waste management hierarchy. Nigeria is still lagging behind technologically in the plastic waste recycling value chain. In spite of the technological limitations, a number of innovative ideas stand out. These include densification, pelletization and production of plastic flakes for export, use of plastic in construction and fashion materials and waste to chemical through pyrolysis.